INJEKTO Brings Desktop Injection Molding With 3D Printed Molds to the Workshop – 3DPrint.com

INJEKTO mold backer. Image courtesy of Action Box.

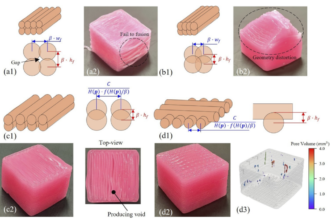

The INJEKTO 3 is a desktop injection molding unit that costs $2,600. The unit can dispense 50 mL shots at an injection pressure of 40 MPa and an air pressure of 90 PSI. It can use metal molds, but also use 3D printed mold inserts along with metal mold backers. In this way, this injection mold unit could be the ideal companion for your 3D printing setup. The machine has been tested for PA6, PA66, TPU, TPE, ABS, PP, PE, PET, PETG, and PC so far.

The machine comes with a guide that specifies the temperature to set. To work it, you add resin pellets to the top. Once melted, you place them in the mold. A ram is then pushed into the mold, and the plastic is injected into the mold. A green button presses in the ram, a red button pulls it out again. After cooling, you can extract your part.

INJEKTO 3 plastic-injected parts made with 3D printed molds. Image courtesy of Action Box.

The key to making this thing flexible is metal mold backers, and the company helps you design your individual molds to work with them. But you could also machine your own or use existing molds. That openness will really resonate with people looking to create series based on 3D prints that can become popular suddenly. The company wants people to use the system with polymer molds, but also with metal ones for bigger runs. That could make it a versatile tool for a workshop.

The company is targeting this product at entrepreneurs, labs, workshops, makerspaces, schools, and teams at companies. The company says that,

“We built INJEKTO 3 to bridge the gap between 3D printing and industrial injection molding, giving small teams access to real molded parts early in the development process. Our company mission is to put the power of manufacturing into the hands of everyday creators by developing reliable, easy-to-use machines that encourage experimentation, learning, and sustainable production.”

The company also indicated that people are, “producing functional prototypes, small batch manufacturing, products with intent to sell, and educational manufacturing projects (teaching the injection molding process in high schools and universities).”

The INJEKTO really seems like a well-thought-out machine. Simple is hard, and this seems like a straightforward, simple way to injection mold at home or in a small workshop. I really like that you can use different backers with this, and that it seems versatile. Maybe I could try SLA molds on this setup, or try a friend’s CNC to make my first metal mold, or move from short runs to longer ones as the product becomes successful. I think this will resonate with the experimental inventor crowd at home and in makerspaces specifically.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.