Multi-Axis Robots Push Silicone 3D Printing Further – 3DPrint.com

In the paper titled “Robot-assisted multi-axis embedded silicone printing for free-form volumetric models,” Nottingham Trent University, The Chinese University of Hong Kong, and the University of Manchester researchers have collaborated to put forth an interesting way to produce silicone parts. Haillin Sun, Yingjun Tian, Chenyu Xu, Mahdi Bodaghi, Fei Gao, and Guoxin Fang have used a robot arm to print silicone in a gel.

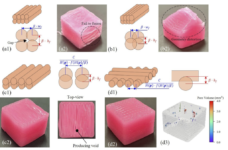

Proposed multi-axis embedded silicone printing (ESP) system for fabricating free-form volumetric silicone models within a gel-like supporting matrix.

Similar to FRESH, NOSE, SLAM, and RLP, this process uses an extruder to extrude material into a supporting gel. Through using a six-axis arm, the team can create novel toolpaths and come up with geometries with more geometric fidelity and better structures. This could make a real difference in organic structures and structures that can be conformal to the body, for example. With a new slicing and a “boundary-conformal staggered toolpath algorithm,” they hope to see better results. By overlapping toolpaths with variable widths, depending on local part geometry, they hope to achieve more conformal shapes with better surface quality by controlling local extrusion volume. It’s kind of input shaping combined with FRESH.

This is a cool new approach that, if successful, will put pools in lawyers’ yards. There is a huge opportunity in large silicone 3D printed structures, especially those designed to fit the human body. Staggered 3D printing, by going back in the opposite layer along with different extrusion speeds, overhangs can result in parts with good surface quality and good adhesion. Taking into account layer heights, layer widths, and geometry will lead to a more precise extrusion. This is similar to what Bambu is doing with its cameras and sensors. But, in syringe extrusion and Direct Ink Write or systems like this one, determining the right extrusion volume, speed, and pressure is even more complex. The team maintains that through better modulating these factors, they have gotten better results. In this case, their calculations were a bit more complex because the cross-sectional shape of the extruded material changes from oval to round depending on the speed. And the constant movement of the nozzle and the fact that it was printing in lots of different positions also, of course, have effects. Through better volume control over the ink deposition, they were able to further improve results.

In this case, the team 3D printed in Carbopol. Carbopol is a polymer made by Lubrizol. It’s a crosslinked polyacrylic in a family of polymers called carbomers. These are used widely as an emulsifier, thickener, dispersion agent & stabilizer in things like moisturizer, drugs, hair gel, shampoos, toothpastes, eye drops, sunscreen, and much else. Purell, Cerave, Vaseline, and many other products you use every day contain carbomers, with Carbopol being the most popular.

The robot arm used is a popular Universal Robots UR5e, which has a maximum 5-kilo payload and 850mm reach. The robot costs around $38,000. The RoboDK software was used for motion and inputs. The build materials were based on Smooth On materials, Ecoflex 0030, Dragon Skin 10, and Mold Star 30. Measured error rates for surface errors were below 1%; dimensional accuracy ranged from ±0.49 mm to ±0.20 mm; and the team found few pores.

The team then made soft robotics components, medical models, and wearables to test out their approach. Much of the paper focuses on how they improved results through tweaking and process improvements. This work could lead to more large-scale silicone 3D printing, especially of conformal shapes. If we look at technologies such as orthotics, implant liners, and scoliosis braces, this technology could make a real difference. Especially in a large, soft, movable structure such as a scoliosis brace, something like this printer could be super useful. They are printing the right shapes, including deformed ones, which could really deliver a much better product to users. Many medical devices, as well as sporting goods, could be improved with reliable, larger-format silicone extrusion methods. We would also expect that, with even better toolpathing, objects will become stronger and be able to embed more functionality. This work could point to an interesting new pathway to silicone 3D printed products.

Images courtesy of Sun et al., via Virtual and Physical Prototyping

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.